Today we will learn about what is casting its working process advantages disadvantages and main casting terminology. Investment casting has a higher cost associated with it.

Ppt Chapter 11 Metal Casting Processes Powerpoint

Ppt Chapter 11 Metal Casting Processes Powerpoint

advantages and disadvantages of investment casting

advantages and disadvantages of investment casting is a summary of the best information with HD images sourced from all the most popular websites in the world. You can access all contents by clicking the download button. If want a higher resolution you can find it on Google Images.

Note: Copyright of all images in advantages and disadvantages of investment casting content depends on the source site. We hope you do not use it for commercial purposes.

Advantages of investment casting 1.

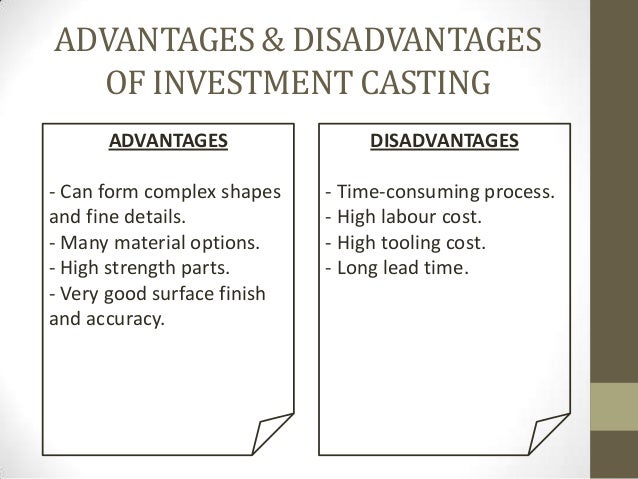

Advantages and disadvantages of investment casting. Lost wax investment casting advantages. Investment casting allows for a quality end product and rapid turnaround not to mention offers an array material sizes and configuration options. November 4 2017 uncategorized saffroshine at admin.

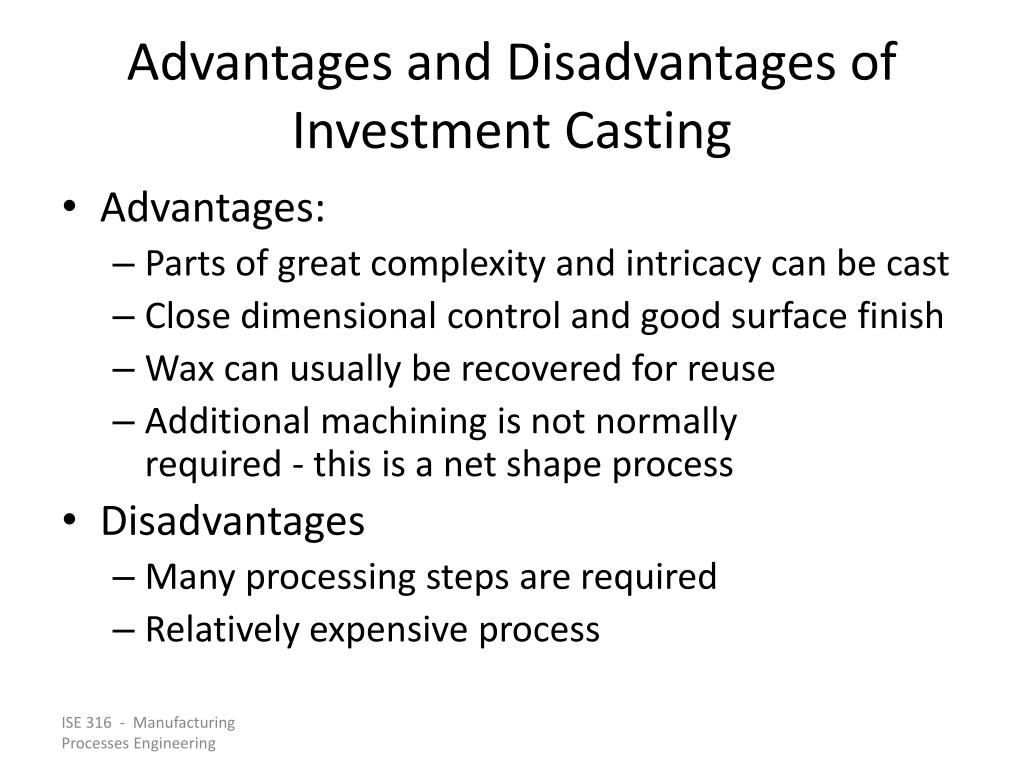

Dimensional accuracy is good. Advantages and disadvantages of investment casting. Lost wax casting is also called as investment casting and is one of the oldest technique carried out to obtain precision casting.

This may be the best choice for your casting need. Many intricate forms with undercuts can be cast. Certain unmachinable parts can be cast to preplanned shape.

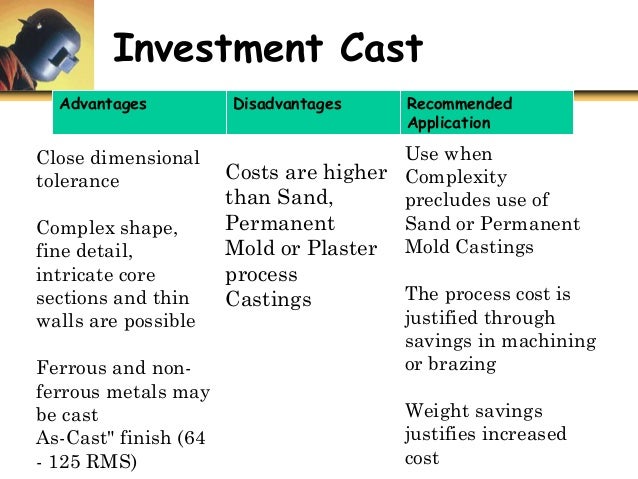

Many intricate forms with undercuts can be cast. But before making your decision here are some of the advantages and disadvantages of the process to help you better discern if its the right. In fact it is more expensive than sand casting permanent mold and the plaster casting process.

When compared to other types of casting processes investment casting needs a longer product cycle time. A very smooth surface is obtained with no parting line. Design casting versatility thompson investment casting works with over 100 different ferrous and non ferrous casting alloys.

It may be used to replace die casting where short runs are involved. Advantages disadvantages of investment casting advantages of investment casting 1. A very smooth surface is obtained with no parting line.

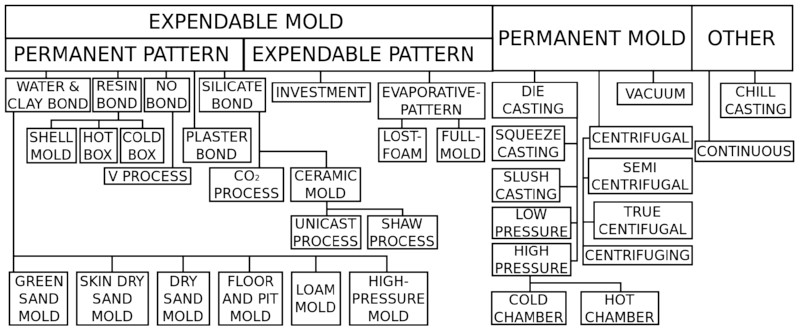

This allows our investment casting process to be used in a variety of industries as it produces a wide range of cast and casting based assemblies. Advantages of investment casting 1. Steps in investment casting process advantages and disadvantages investment casting process the investment casting process which is commonly referred to as the lost wax method originated in and around the fourth millennium bc.

A very smooth surface is obtained with no parting line. Disadvantages of investment casting 1. Casting is defined as a manufacturing process in which molten metal pure into a mold or a cavity of desire shape and allow to solidify which form a predefine shape.

Many intricate forms with undercuts can be cast. There is a limitation on the size of parts that can be casted. There are two main processes of investment casting water glass process silica sol process.

Casting Vs Fabrication 100 000 Cumulative Saving After 5

Casting Vs Fabrication 100 000 Cumulative Saving After 5

Me 330 Manufacturing Processes Casting Processes Cont

Me 330 Manufacturing Processes Casting Processes Cont

Chapter 3 Metal Work Casting Process And Heat Treatment On

Chapter 3 Metal Work Casting Process And Heat Treatment On

Castech Foundries On Twitter A List Of Investmentcasting

Castech Foundries On Twitter A List Of Investmentcasting

Metal Casting Processes 1 2 3 4 5

Metal Casting Processes 1 2 3 4 5

Precision Investment Casting Process Applications

Precision Investment Casting Process Applications

Ppt Chapter 12 Expendable Mold Casting Processes Ii Ein

Ppt Chapter 12 Expendable Mold Casting Processes Ii Ein